Our Facilities

500 Tons Of Metallic Moulds

A Brand New Spectrometer

Physical & Chemical Testing Laboratory

Pit Type & Tilting Furnaces

Infrastructure & the technology we use

Having expanded substantially since its inception, Spin-N-Cast has grown to become a reliable manufacturer of metallic components.

The backbone of any manufacturing process is the infrastructure and technology that supports it. At Spin-N-Cast, we have made certain that we use only the best production material and superior machinery. This is evident from our sprawling foundry unit.

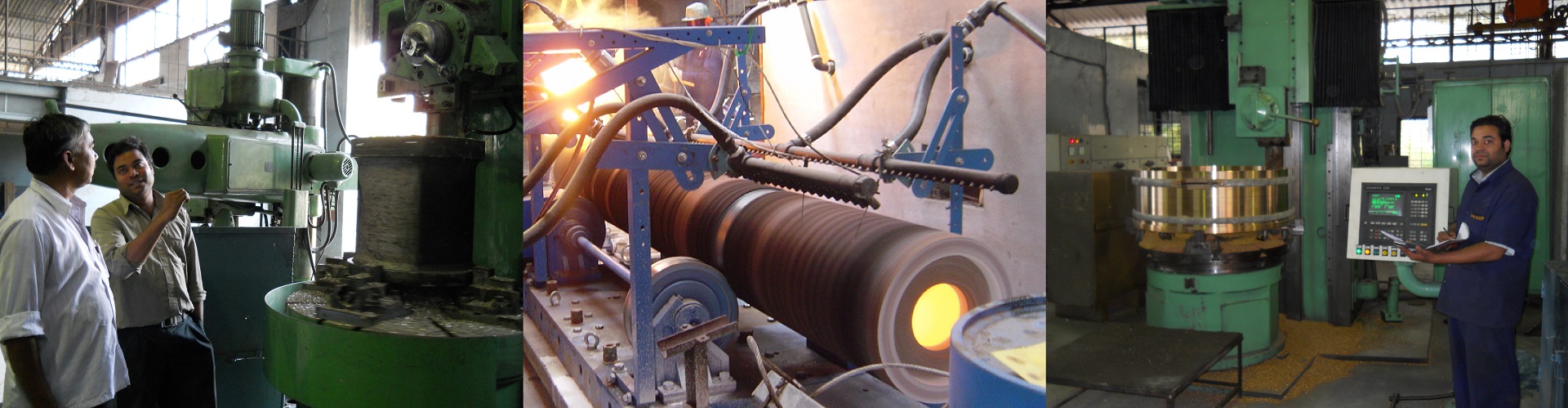

Our arsenal (the foundry unit) is equipped with all that is required to produce topnotch castings, including (but not limited to):

- Pit type & tilting furnaces (oil-fired, with a capacity of 200-3,500 kilograms)

- 500+ tons of metallic moulds

- Physical & chemical testing laboratory

- A brand new Spectrometer

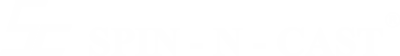

Our machine shop consists of:

- Over 20 machine tools including heavy-duty lathes (up to center height 36”), milling (1600 x 450 x 300) and radial drilling machines, CNC vertical turrets, horizontal and vertical boring mills, slotting and cutting machines

- Measuring instruments including micrometers, vernier scales, height & dial bore gauges (up to 1,200 mm)

- A brand new VTL with a table diameter of 2,000 mm for the precise machining of larger components

We specialize in:

- Churning out non-ferrous centrifugal and chill castings in copper-based alloys (ASTM, BS 1400, DIN, IS standards).

- Producing castings in the range of 50 mm OD to 1600 mm OD and up to 3300 mm in length. The proof-machined weight may go up to 2000 kg.

- Offering over 500 tons of metallic moulds to cater to all sizes of castings.

Note: Certain test services are being availed from third party inspecting agencies